Some additional settings must be made to configure and program a Sick Safety PLC via the EoE communication protocol.

Prerequisites

The instruction is based on:

- ctrlX CORE V1.18

- ctrlX CORE EtherCAT Master App V1.18

- ctrlX PLC Engineering V1.18

- ctrlX I/O Engineering V1.18

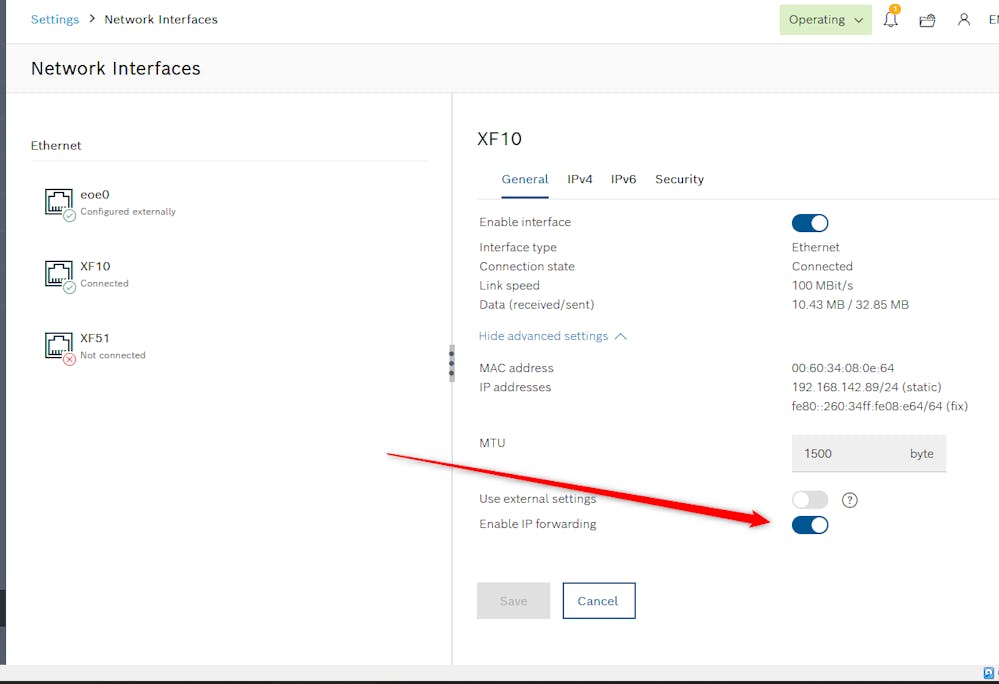

Enable IP forwarding in the ctrlX CORE on the eoe0 connector

- Open the ctrlX CORE Web interface.

- Go to the menu point "Settings" and chose the option "Network Interfaces".

- Activate the switch "Enable IP forwarding".

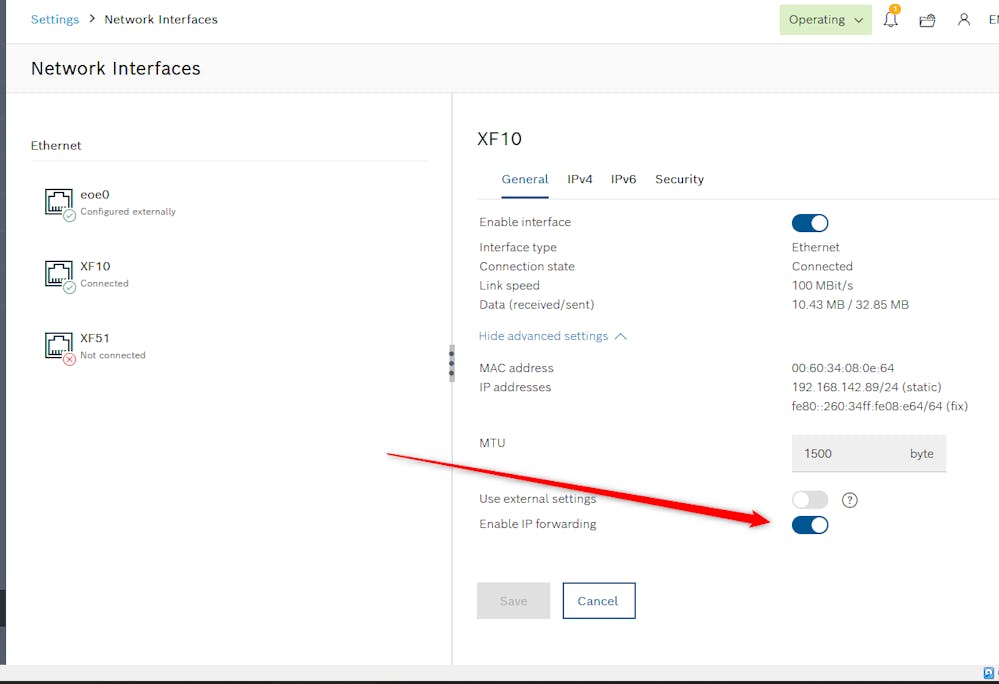

Enable IP forwarding in the ctrlX CORE for the XF10 connector

- Open the ctrlX CORE Web interface.

- Go to the menu point "Settings" and chose the option "Network Interfaces".

- Activate the switch "Enable IP forwarding".

Enable IP forwarding of XF10 interface

Setup the I/O configuration

- Open the ctrlX I/O Engineering

- Choose Scan for Devices… from the context menu from the item “ethercatmaster”.

- Double click on the device "Flexi_Soft_Ethercat_Gateway".

- Activate the checkbox "Virtual Ethernet port".

- Activate the window ethercat master and go there to the menu "EoE".

- Please check if the configuration of the EoE is ok.

- The IP address is the same number as the station address. In this example the IP address is 172.31.254.3 and the station address is 3.

Adjustment of Windows 10

- Now you have to add a route to the windows system.

- Please start the Dos Box as administrator with the command "cmd".

- Enter the command "route add -p 172.31.254.0 MASK 255.255.0.0 192.xxx.xxx.xx.

Adjustment of the Sick Communication via Gateway

- Start the program "SafeLogic Desinger 1.8.0 SP1".

- Edit "com. interface settings".

- Setup the communication settings

- Then close this dialog and go to the communication settings.

- Check the communication.

- If this was successful, activate the profile.

Now you can work with the Sick PLC without an additional external connection.